what does a sit need to hold nuclear waste

Storage and Disposal of Radioactive Waste matter

(Updated May 2021)

- Radioactive wastes are stored so as to avert whatever chance of radiation exposure to people, or any pollution.

- The radioactive decay of the wastes decays with fourth dimension, providing a strong incentive to shop loftier-level waste for most 50 years before disposal.

- Disposal of low-level waste matter is straightforward and can exist undertaken safely almost anywhere.

- Storage of used fuel is usually under h2o for at least five years and and then often in dry storage.

- Deep geological disposal is widely agreed to be the best solution for final disposal of the most radioactive waste produced.

Most low-level radioactive waste product (LLW) is typically sent to land-based disposal immediately following its packaging for long-term management. This ways that for the bulk (~90% by volume) of all of the waste product types produced by nuclear technologies, a satisfactory disposal ways has been developed and is being implemented around the world.

For used fuel designated as high-level radioactive waste product (HLW), the kickoff step is storage to let disuse of radioactive decay and heat, making handling much safer. Storage of used fuel may be in ponds or dry casks, either at reactor sites or centrally. Beyond storage, many options have been investigated which seek to provide publicly adequate, safe, and environmentally audio solutions to the terminal management of radioactive waste. The most widely favoured solution is deep geological disposal. The focus is on how and where to construct such facilities.

Used fuel that is not intended for directly disposal may instead exist reprocessed in order to recycle the uranium and plutonium it contains. Some separated liquid HLW arises during reprocessing; this is vitrified in drinking glass and stored awaiting final disposal.

Intermediate-level radioactive waste (ILW) that contains long-lived radioisotopes is also stored pending disposal in a geological repository. In the USA, defence-related transuranic (TRU) waste product – which has similar levels of radioactivity to some ILW – is tending of in the Waste product Isolation Pilot Plant (WIPP) deep geological repository in New Mexico. A number of countries dispose of ILW containing brusk-lived radioisotopes in near-surface disposal facilities, equally used for LLW disposal.

Some countries are at the preliminary stages of their consideration of disposal for ILW and HLW, whilst others, such equally Finland and Sweden, have made proficient progress. Finland's Onkalo repository is expected to start operating in 2023. It volition be the start deep geological repository licenced for the disposal of used fuel from civil reactors.

The post-obit table sets out the commonly accepted disposal options. When considering these, information technology should exist noted that the suitability of an option or idea is dependent on the wasteform, volume, and radioactive decay of the waste product. As such, waste management options and ideas described in this section are non all applicable to unlike types of waste matter.

Ordinarily-accepted disposal options

| Choice | Suitable waste material types | Examples |

| Near-surface disposal at ground level, or in caverns below footing level (at depths of tens of metres) | LLW and brusque-lived ILW |

|

| Deep geological disposal (at depths betwixt 250m and 1000m for mined repositories, or 2000m to 5000m for boreholes) | Long-lived ILW and HLW (including used fuel) |

|

Boosted ideas have also been considered and discounted in the past (meet section on Other ideas for disposal beneath, and data paper on International Radioactive waste Disposal Concepts).

Most-surface disposal

The International Atomic Energy Bureau (IAEA) definitionb of this choice is the disposal of waste, with or without engineered barriers, in:

- Near-surface disposal facilities at ground level. These facilities are on or below the surface where the protective roofing is of the order of a few metres thick. Waste containers are placed in constructed vaults and when total the vaults are backfilled. Eventually they volition be covered and capped with an impermeable membrane and topsoil. These facilities may incorporate some course of drainage and perhaps a gas venting system.

- Nigh-surface disposal facilities in caverns below footing level. Unlike near-surface disposal at ground level, where the excavations are conducted from the surface, shallow disposal requires underground excavation of caverns. The facility is at a depth of several tens of metres below the World's surface and accessed through a drift.

The term most-surface disposal replaces the terms 'shallow land' and 'ground disposal', simply these older terms are still sometimes used when referring to this option.

These facilities volition be affected by long-term climate changes (such as glaciation) and this event must be taken into account when considering rubber, as such changes could disrupt these facilities. This blazon of facility is therefore typically used for LLW and short-lived ILW with one-half-lives of upwards to 30 years.

About-surface disposal facilities at ground level are currently in performance in:

- Uk – LLW Repository at Drigg in Cumbria operated by U.k. Nuclear Waste Management (a consortium led past AECOM with Studsvik UK, Serco, and Orano) on behalf of the Nuclear Decommissioning Authority.

- Spain – El Cabril LLW and ILW disposal facility operated past ENRESA.

- France – Centre de l'Aube operated by Andra.

- Japan – LLW Disposal Centre at Rokkasho-Mura operated by Japan Nuclear Fuel Express.

- USA – five LLW disposal facilities: Texas Meaty facility near the New Mexico edge, operated by Waste Control Specialists; Barnwell, Due south Carolina operated by EnergySolutions; Clive, Utah (EnergySolutions); Oak Ridge, Tennessee (EnergySolutions); and Richland, Washington – operated past American Ecology Corporation.

Well-nigh-surface disposal facilities in caverns below ground level are currently in operation in:

- Sweden – the SFR final repository for short-lived radioactive waste material at Forsmark, where the depth of the facility is 50m under the Baltic seabed – operated by the Swedish Nuclear Fuel and Waste Management Company (SKB)c.

- Finland – an underground repository at Olkiluoto for LLW and ILW has been in operation since 1992. A similar facility at Loviisa was commissioned in 1997. The depth of these is about 100 metresd.

Deep geological disposal

The long timescales over which some waste remains radioactive has led to the idea of deep disposal in surreptitious repositories in stable geological formations. Isolation is provided by a combination of engineered and natural barriers (rock, common salt, clay) and no obligation to actively maintain the facility is passed on to hereafter generations. This is ofttimes termed a 'multi-barrier' concept, with the waste packaging, the engineered repository, and the geology all providing barriers to prevent the radionuclides from reaching humans and the environs. In addition, deep groundwater is generally devoid of oxygen, minimising the possibility of chemic mobilization of waste.

Deep geological disposal is the preferred option for nuclear waste product direction in most countries, including Argentina, Australia, Belgium, Canada, Czech republic, Finland, France, Nippon, holland, Republic of Korea, Russia, Spain, Sweden, Switzerland, the UK, and the USA. Hence, there is much information available on dissimilar disposal concepts; a few examples are given here. The only purpose-congenital deep geological repository that is currently licensed for disposal of nuclear textile is the Waste product Isolation Pilot Constitute (WIPP) in the USA, merely it does not accept a licence for disposal of used fuel or HLW. Plans for disposal of spent fuel are peculiarly well advanced in Finland, likewise equally Sweden, France, and the USA, though in the United states there have been political delays. In Canada and the UK, deep disposal has been selected and the site selection processes have commenced.

Mined repositories

The most widely proposed deep geological disposal concept is for a mined repository comprising tunnels or caverns into which packaged waste matter would be placed. In some cases (eastward.thou. moisture rock) the waste containers are then surrounded by a material such as cement or clay (usually bentonite) to provide another barrier (chosen buffer and/or backfill). The selection of waste product container materials and design, equally well as the buffer/backfill material varies depending on the type of waste to be contained and the nature of the host stone-type available.

Excavation of a deep surreptitious repository using standard mining or civil engineering engineering science is limited to accessible locations (e.g. under state or nearshore), to rock units that are reasonably stable and without major groundwater period, and to depths of between 250m and 1000m. The contents of the repository would be retrievable in the brusk term, and if desired, longer-term.

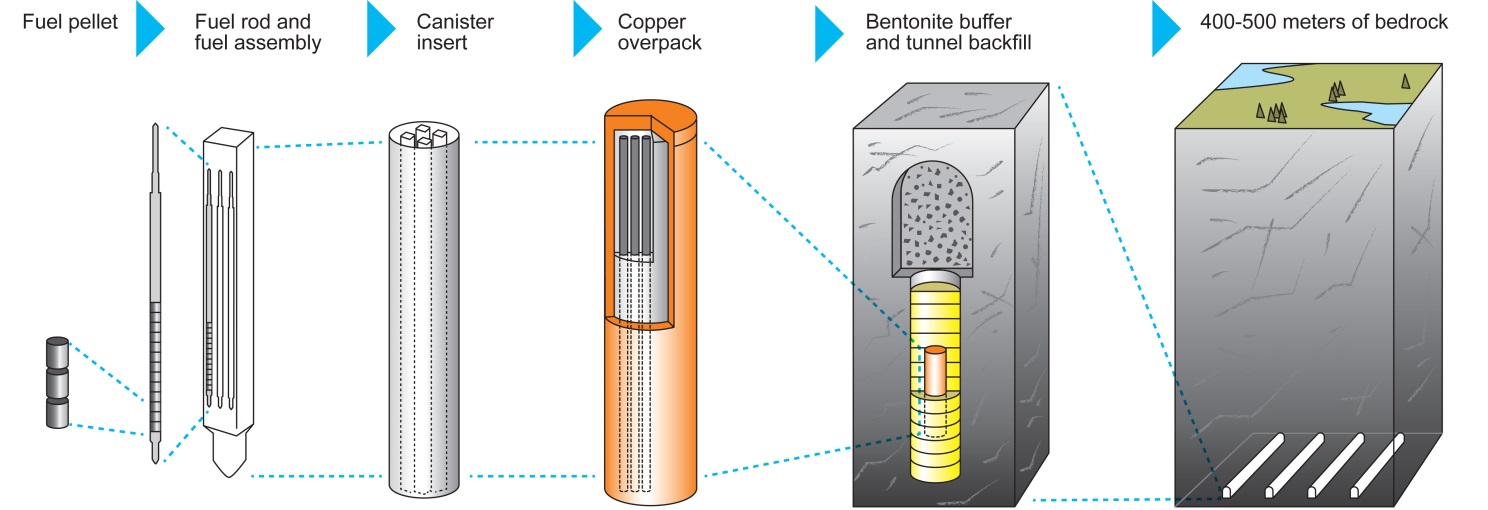

The Swedish proposed KBS-3 disposal concepte uses a copper container with a steel insert to incorporate the spent fuel. Afterwards placement in the repository about 500 metres deep in the bedrock, the container would exist surrounded past a bentonite dirt buffer to provide a very loftier level of containment of the radioactive decay in the spent fuel over a very long time period. In June 2009, the Swedish Nuclear Fuel and Waste Direction Company (SKB) appear its conclusion to locate the repository at Östhammar (Forsmark).

Finland's repository program is as well based on the KBS-three concept. Spent nuclear fuel packed in copper canisters volition be embedded in the Olkiluoto bedrock at a depth of effectually 400 metres. The land's radioactive waste management company, Posiva Oy, expects the repository to begin disposal operations in 2023. Its construction was licensed in November 2015.

The deposits of native (pure) copper in the world accept proven that the copper used in the final disposal container tin can remain unchanged within the bedrock for extremely long periods, if the geochemical conditions are advisable (low levels of groundwater flow). The findings of ancient copper tools, many thousands of years erstwhile, also demonstrate the long-term corrosion resistance of copper, making it a apparent container fabric for long-term nuclear waste storage.

Multi-barrier disposal concept (Image: Posiva)

Deep boreholes

Also equally mined repositories, which have been the focus of most international efforts and so far, deep borehole disposal has been considered as an option for geological isolation for many years, including original evaluations by the U.s. National Academy of Sciences in 1957 and more recent conceptual evaluations. In contrast to contempo thinking on mined repositories, the contents would not be retrievable.

The concept consists of drilling a borehole into basement rock to a depth of up to about 5000 metres, emplacing waste matter canisters containing used nuclear fuel or vitrified nuclear waste from reprocessing in the lower 2000 metres of the borehole, and sealing the upper 3000 metres of the borehole with materials such as bentonite, cobblestone or concrete. The disposal zone of a single borehole could thus contain 400 steel canisters each five metres long and i-3rd to half a metre in diameter. The waste containers would be separated from each other by a layer of bentonite or cement.

Boreholes can be readily drilled offshore (as described in the section below on sub seabed disposal) every bit well as onshore in both crystalline and sedimentary host rocks. This capability significantly expands the range of locations that tin exist considered for the disposal of radioactive waste material.

Deep borehole concepts take been developed (just not implemented) in several countries, including Denmark, Sweden, Switzerland, and the U.s.a.. Compared with deep geological disposal in a mined underground repository, placement in deep boreholes is considered to be more than expensive for large volumes of waste. This option was abandoned in countries such as Sweden, Finland, and the USA, largely on economic grounds. The borehole concept remains an attractive proposition for the disposal of smaller waste material forms including sealed radioactive sources from medical and industrial applicationsf.

An Oct 2014 US Department of Energy (DOE) study said: "Preliminary evaluations of deep borehole disposal betoken a high potential for robust isolation of the waste, and the concept could offer a pathway for earlier disposal of some wastes than might be possible in a mined repository." In January 2016 the DOE commissioned a team led by Battelle to drill a 4880-metre test borehole into crystalline basement rock in North Dakota, but the project was later scrapped following local opposition.

Mined repositories – evolution examples

Boom clay & Opalinus clay, Europe

The Belgian disposal concept proposes that spent fuel and HLW is placed in high integrity steel containers and then emplaced in excavated tunnels 230 metres deep within a ductile (self-sealing) clayg – the Nail clay. The very low permeability of the clay leads to virtually no groundwater flow over long time periods. Waste would exist backfilled with excavated clay or, alternatively, could be emplaced into unlined secondary tunnels where the dirt would exist allowed to 'creep' into contact with the waste containers. Similar systems have been proposed in the Netherlands and, using less plastic clays, in France and Switzerlandh (Opalinus clay). Clay is more often than not suitable for rut-generating HLW, and the OECD Nuclear Free energy Agency has a 'Clay Club' researching this.

The French radioactive waste product disposal agency, Andra, is designing a deep geological repository in clays at Bure in eastern France. This will be for disposal of vitrified HLW and long-lived ILW. The repository is designed to operate at up to 90ºC, which is likely to be reached about 20 years after emplacement.

Yucca Mountain, Us

At the end of 1987, the Nuclear waste Policy Act was amended to designate Yucca Mount, located in the remote Nevada desert, as the sole US national repository for spent fuel and HLW from nuclear power and military defence programs. An application by the The states DOE to construct the repository was submitted in June 2008.

The repository would exist 300 metres underground in an unsaturated layer of welded volcanic tuff stone. Waste would be stored in highly corrosion-resistant double-shelled metal containers, with the outer layer fabricated of a highly corrosion-resistant metal alloy, and a structurally stiff inner layer of stainless steel. Since the geological formation is essentially dry out, information technology would non be backfilled but left open up to some air circulation. Drip shields made of corrosion-resistant titanium would cover the waste matter containers to divert possible future h2o percolation and provide protection from possible falling rock or debris. Containment relies on the extremely low water table, which lies approximately 300 metres beneath the repository, and the long-term durability of the engineered barriers.

The project has experienced many delays since its inception and following the 2009 presidential election the Barack Obama assistants decided to abolish iti. However, in June 2010, the Nuclear Regulatory Commission's Diminutive Safety and Licensing Lath (ASLB) rejected the DOE's movement to withdraw the licence application, and in Baronial 2013 the federal Appeals Court ordered the NRC to resume its review of the DOE'due south application for a licence to construct and operate the Yucca Mount repository. The final volumes of the NRC's safety evaluation report were published early in 2015, which incorporate the bureau's technical review of safety of the repository. In May 2016, the NRC released its final supplement to the US DOE'southward environmental impact statement on the proposed Yucca repository. Both the ecology bear on cess and the NRC's experts established that the repository design would prove prophylactic for one million years.

Disposal in layered common salt strata or domes

Geological salt environments have a very low charge per unit (possibly fifty-fifty an absenteeism) of groundwater flow and characteristic gradual self-sealing of the excavations due to creep of the salt, which is plastic. Common salt is generally suitable for heat-generating HLW, and the OECD Nuclear Energy Agency has a 'Salt Club' researching this.

The Waste material Isolation Pilot Establish (WIPP)j in New Mexico for defense transuranic wastes (long-lived ILW) has been operational since 1999. For this repository natural rock salt is excavated from a Permian layer several metres thick, between other types of stone, 650 metres beneath ground level. The wastes placed in these excavations contain large volumes of long-lived ILW, normally in steel drums. These are then placed on pallets and stowed in excavated rooms or caverns. The salt is plastic and will eventually seal the wastes and isolate them permanently. Containment of the radionuclides in the wasteform by and large relies on the almost complete absence of water flow in the salt. To date over 90,000 cubic metres of ILW has been disposed of at WIPP.

Table salt environments are also available in northern Deutschland and kingdom of the netherlands although these are salt domes rather than bedded formations. In Germany, the former common salt mines at Asse and Morsleben have been used for LLW and ILW disposal though this has now been suspended. The decommissioning procedure is now being investigated to decide the method for backfilling and sealing the repository.

Following an exhaustive site selection process the land government of Lower Saxony in 1977 declared the common salt dome at Gorleben to be the location for a German national centre for disposal of radioactive wastes. Following a new law in early 2017, Gorleben is at present considered one possible site for geological disposal of HLW. The site could exist available as a final repository from 2025, with a decision to be made about 2019. Some €i.5 billion was spent over 1979 to 2000 researching the site. Work then stopped due to political edict, but resumption of excavation was approved following a change of government in 2009. In September 2020 Germany launched a new search for a disposal site, naming 90 possible locations (but not Gorleben).

Nirex Phased Disposal Concept, UK

The UK's Nirex Phased Disposal Concept (or Phased Geological Disposal Concept) has been developed for relatively large volumes of ILW and LLW, usually cemented into stainless steel containersk. These containers would be emplaced into a repository in a host rock surroundings below the water table. The waste matter would be monitored and remain retrievable and the groundwater managed to forbid contact with the wastes, until such a time that the repository is sealed. When this happens, the waste will be surrounded (backfilled) past specially formulated cement and the repository immune to resaturate. The cement would provide a long-lasting alkaline surroundings that contributes to containment of the waste by preventing many radionuclides from dissolving in the groundwater. Similar cement-based schemes for ILW disposal have been proposed in France, Nihon, Sweden and Switzerland.

Multinational repositories

Not all countries are adequately equipped to shop or dispose of their ain radioactive waste material. Some countries are limited in expanse, or have unfavourable geology, and therefore siting a repository and demonstrating its safety could be challenging. Some smaller countries may non have the resource to take the proper measures on their own to ensure adequate safety and security, or they may non have enough radioactive waste matter to make construction and operation of their own repositories economically feasible.

It has been suggested that at that place could be multinational or regional repositories located in a willing host country that would have waste from several countries. They could include, for example, use past others of a national repository operating inside a host state, or a fully international facility owned by a private visitor operated by a consortium of nations or fifty-fifty an international organisation. However, for the time being, many countries would not accept nuclear waste from other countries under their national laws. National policies towards radioactive waste management are listed in National Radioactive waste Direction Appendix two: National Policies & Funding and the information paper on International Nuclear Waste Disposal Concepts.

Acting waste storage and send

Specially designed acting surface or sub-surface storage waste product facilities are currently used in many countries to ensure the condom storage of hazardous radioactive waste awaiting the availability of a long-term disposal option. Acting storage facilities are by and large used for ILW and HLW, including used nuclear fuel from reactors.

Storage ponds

Storage ponds at reactors, and those at centralized facilities such as CLAB in Sweden, are seven-12 metres deep to allow the racked fuel assemblies to be covered by several metres of water. The fuel assemblies are typically nigh four one thousand long and standing on end. The multiple racks are fabricated of metal with neutron absorbers incorporated in it. The circulating water both shields and cools the fuel. These pools are robust constructions made of thick reinforced concrete with steel liners. Ponds at reactors may exist designed to concur all the used fuel for the life of the reactor, only commonly the blueprint assumes some removal of cooled fuel for reprocessing or to dry storage.

Primal Interim Storage Facility (CLAB), Sweden. Image: SKB

Dry storage

Some storage of fuel assemblies which accept been cooling in ponds for at least 5 years is in dry casks or vaults, typically with air apportionment inside concrete shielding. Dry storage has been used at The states nuclear power plants since 1986, and at least ane-third of the total The states used fuel is now in dry storage casks. Facilities are at most of the nuclear power plant sites (including some closed ones). As of the end of 2019, 3203 casks had been loaded at 72 interim spent fuel storage installations (ISFSIs) in the USA. Transfer from wet storage to dry out casks at a power plant site may apply special shielded transfer casks, which are less robust than those used for ship beyond the site. Casks may contain a sealed canister which can be transferred from ane kind of cask to another.

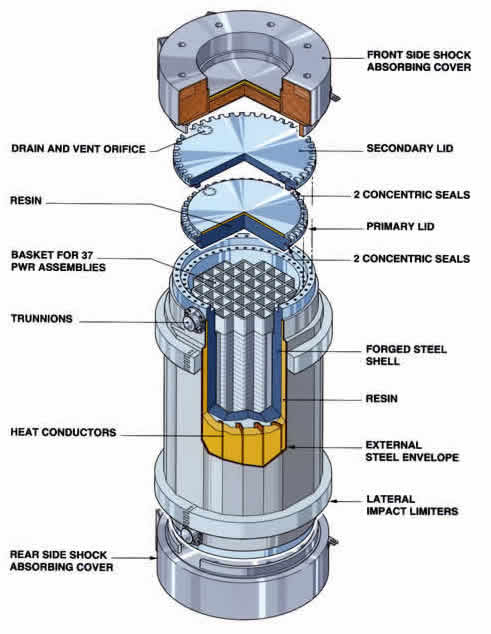

Multi-purpose canisters

Sealed multi-purpose canisters (MPCs), also chosen dual-purpose canisters (DPCs), each holding up to 89 fuel assemblies with inert gas, are commonly used for transporting, storing and eventual disposal of used fuel. MPCs are independent inside robust overpacks – metal for transport, or mainly concrete for storage. Each MPC, constructed using 13 mm welded stainless steel with a secure hat and internal fuel basket to hold and continue the fuel assemblies separate, is designed for up to 45 kW oestrus load. MPCs accept standard external dimensions and the number of fuel assemblies actually loaded into 1 depends on their characteristics. Some are double-walled (DWC), with helium in between the layers. Once an MPC is loaded the contents should never need to be handled once again.

The IAEA publishes radioactive textile transport regulations – notably Regulations for the Safe Transport of Radioactive Material, IAEA Safety Standards Serial No. SSR-6 (Rev.1).

Holtec's MPC contains a 68-cell fuel basket for BWR fuel, a 24-cell flux-trap, or a 32-jail cell non-flux trap fuel basket for PWR fuel. Some accept neutron-absorbing Metamic-HT fuel baskets and liners with high thermal conductivity, enabling relatively-hot three-yr-old spent fuel to be placed in them. Since 2013 Holtec also makes double-walled canisters (DWCs) for the UK and Ukraine, with the same standard external dimensions.

High-capacity MPCs are able to hold 37 PWR or 87-89 BWR fuel assemblies. Others take just 12 PWR or 32 BWR fuel assemblies. With some pocket-size canisters – iv PWR/9BWR – iv can be fitted into a standard transport cask. Areva has a large canister blueprint belongings 21 PWR or 44 BWR fuel assemblies.

Storage casks and systems

For storage, each MPC is enclosed in a ventilated storage module or overpack made of concrete and steel. These are commonly standing on the surface, about 6 metres high, cooled by air convection, or they may be horizontal in banks, or vertical and beneath grade, with simply the tops showing. The modules are robust and provide full shielding. At a nuclear power found, a shielded transfer cask is used to move the MPC from the used fuel pool to a storage module. Holtec's transfer casks for onsite use are called HI-TRAC.

A complimentary-standing higher up-ground organisation is Holtec's Hi-STORM 100, which accommodates a variety of sealed stainless steel MPCs vertically inside ventilated physical and steel overpacks standing on a concrete pad. The 165-tonne overpack has 65 cm of physical inside steel casing for shielding. This system is used at many US plants. A below-basis variant is Hi-Tempest 100U, and a more sophisticated version of this is Holtec's Howdy-Tempest UMAX storage system, which is already deployed at two U.s.a. nuclear ability plant sites, and proposed for the HI-Store CIS facility in New Mexico (meet below). HI-STORM UMAX stores the canisters containing used fuel in ventilated vertical steel and concrete cavity enclosure containers v metres high below footing, with massive lids at basis level. The containers are set up in a 7.6 m deep digging and low-forcefulness concrete grout is backfilled effectually them. The last one-half metre of fill is a reinforced concrete pad. Seismic tolerance is about 2000 Gal.

An above-footing horizontal system is Areva's NUHOMS HSM-H arrangement, used by xx of the 67 ISFSIs at United states of america nuclear plants. The used fuel is sealed in 15 mm thick stainless steel dry storage canisters which are then moved in horizontal shielded transfer casks to large horizontal storage modules, with each hole 5 m long and 2 m bore. Areva claims better heat distribution in these than vertical systems, using conduction more than convection, and also points to no gaps betwixt modules being very safe seismically (1500 Gal) and radiologically. Each canister holds 32-37 PWR fuel assemblies or 61-69 BWR assemblies, in helium. Areva plans to have a Usa-licensed transport cask for NUHOMS by 2020, and meanwhile it has one for high burn down-up fuel. NUHOMS horizontal storage can accommodate a variety of canister designs, and the Areva NUHOMS canisters are compatible with other, e.k. Holtec, vertical storage systems.

In July 2017 the United states Nuclear Regulatory Committee granted Areva TN certification for its NUHOMS Extended Optimized Storage (EOS) dry used fuel storage system. The system is designed for high burn down-up fuel management and reactors in shutdown phase. The large NUHOMS EOS dry shield canisters hold 37 PWR or 89 BWR fuel assemblies. These can be transferred in the EOS TC series transfer cask and stored in NUHOMS EOS HSM physical modules.

Germany's Gesellschaft für Nuklear-Service mbH (GNS), set upwardly in 1977 and owned by the country's iv nuclear utilities, is both an operator of waste material storage and supplier of ii types of cask. The master type are CASTOR casks, more than than grand of which are used in Germany alone for ship and interim storage of spent fuel and HLW. The cask body provides full shielding and allows loading after very short cooling times of loftier burn-upwardly fuel, and they are closed with ii lids. GNS'due south CONSTOR casks are similar but with concrete in the walls and designed for cooler fuels.

A large canister How-do-you-do-Storm FW storage module is a alluvion- and wind-resistant version with high seismic tolerance – one.2 Gal. It holds 37 PWR assemblies, or 89 BWR ones, or 31 VVER-m ones, with maximum heat load 46 kW. The HI-Tempest 190 is the VVER version of the HI-STORM FW. These canisters can hold damaged fuel in special failed fuel containers.

A new large storage cask is HI-Storm MIC (mega-touch capable) designed with EDF Energy in the Uk and having a 100-yr blueprint life. It uses a double-walled MPC, and is heavily shielded.

According to the Acting Storage Partners (ISP) website, there were over 460 NAC and 1265 Orano TN casks storing spent fuel at both operating and decommissioned US nuclear plants equally of June 2019.

A collection of casks or modules comprises an contained spent fuel storage installation (ISFSI), which in the USA is licensed separately from any associated power plant, and is for interim storage only. Well-nigh one-tertiary of United states used fuel is stored thus.

Recognising that long-term management options, specifically for ILW and HLW, may require significant time to be achieved, interim storage arrangements may need to exist extended beyond the time periods originally envisaged.

An indication of the scale of dry storage is that the market for dry out storage casks in the Americas, where in that location is the highest demand, was estimated to be worth approximately $1 billion in 2020.

Some countries, including Commonwealth of australia, Belgium, holland, Germany, Italia, and Switzerland as well place LLW in acting storage, although most LLW is typically sent direct to country-based nearly-surface disposal facilities (run across section above on Most-surface disposal).

ISFSI systems in employ

Many US nuclear power plants, both operational and decommissioned, have independent spent fuel storage installations (ISFSIs).

In the USA a large ISFSI is proposed in Texas, using Areva'south NUHOMS arrangement for up to xl,000 tonnes of used fuel. Waste material Command Specialists applied for a licence for the facility in April 2016, and in March 2018 WCS and Orano USA announced a joint venture – Interim Storage Partners (Isp) – to complete licencing the projection. The NRC expected this to take until May 2021.

Another proposed facility is the HI-STORE consolidated interim storage (CIS) site in New Mexico for the Eddy Lea Free energy Alliance, with an initial capacity of 10,000 storage canisters for about 120,000 tonnes of used fuel. This will occupy almost 15 hectares. A licence application for Howdy-Shop CIS was submitted in March 2017.

Zwilag'south ZZL in Switzerland and Ahaus and Gorleben in Germany are examples of operating long-term above-ground central acting dry storage for HLW.

Ukraine'due south new Key Spent Fuel Storage Facility (CSFSF) will apply a Hi-Tempest 190 ventilated storage arrangement and Hi-STAR 190 casks for transport to the site. Ukraine requires storage to be in double-wall canisters (DWCs), and these are besides used at Sizewell in the United kingdom, giving an increased service life. In Ukraine, Holtec is establishing a centre for supply of dry storage and transport systems to the land's 15 operating reactors and maybe other VVERs around the world.

Lithuania is using GNS CONSTOR M2 dry storage containers at Ignalina, each holding about xc RBMK fuel assemblies. Bulgaria is also using 270 CONSTOR casks for VVER-440 fuel. CONSTOR casks are robust steel casks with physical in the walls and 3 lids, cost-optimized for acting storage of spent fuel which has cooled. They are portable though evidently not designed for shipping used fuel. They are not ventilated and may have a concrete overpack.

Japan's Federation of Electrical Power Companies of Nihon (FEPC) aims to develop an all-aluminum, thinner and lighter basket for a physical cask that would be capable of storing more than spent fuel assemblies at temperatures of upwardly to 400°C. It wants to have the design ready for deployment past the mid-2020s. Most dry storage casks require fuel to be cooled in ponds until the temperature drops to near 250°C.

Casks for deep borehole disposal

Deep Isolation has contracted with NAC International to blueprint and supply corrosion-resistant casks 23 to 31 cm bore and 4.3 m long, each holding one used fuel assembly.

Transport casks

Used fuel assemblies are shipped in 'Type B' casks which are shielded with steel, or a combination of steel and atomic number 82, and tin weigh upwards to 110 tonnes when empty. They contain their highly radioactive payload safely during transport, and may hold from half-dozen to 24 tonnes of used fuel. Some information on transport of used fuel is given in a higher place, considering sometimes very like equipment is used for storage, and more detail about transport generally can be establish in the information paper on Transport of Radioactive Material.

For ship beyond the power plant site, the MPC is put inside a steel ship cask such as a version of the Holtec HI-STAR (STAR = storage, transport and repository). This is classified every bit a Blazon B shipping cask, providing secure shielding and if necessary too some heat dissipation. IAEA SSR-6 regulations specify a maximum of ten mSv/hr dose rate at the external surface, though many customers such as CNNC specify ii mSv/h (these represent measured dose rates of 0.one and 0.02 mSv/h respectively one metre from the surface).

The internal structure of transport casks (using multi-purpose canisters or not) is designed to maintain separation of fuel assemblies even in extreme accidents, and the external construction is designed to maintain rubber containment in farthermost accidents. Both features are tested earlier licensing.

TN24 cask produced by Orano TN (formerly Areva TN)

In the United states of america the Nuclear Regulatory Commission noted virtually 2013: "Over the last xl years, thousands of shipments of commercially generated spent nuclear fuel have been made throughout the United States without causing any radiological releases to the surround or harm to the public." Nearly of these shipments are between different power plants owned by the aforementioned utility, so as to share storage space for used fuel.

Holtec produces a number of Blazon B aircraft packages or casks. Its HI-STAR 100 is a high-capacity system which is engineered to have i sealed multi-purpose canister (MPC) containing a 68-cell fuel basket for BWR fuel or a 32-cell fuel basket for PWR fuel. Information technology has been licensed since 1998 for transport (horizontal) and storage (vertical, on finish). The MPC containing the fuel can exist transferred to HI-Tempest 100 storage systems on an ISFSI pad or below ground surface, exchanging one overpack for another which is engineered for maximum shielding. The MPC is loaded under water. In 2018 Holtec sold its Hullo-STAR 100MB casks to CNNC Everclean in China – a medium-weight version of the cask for blank fuel or fuel in canisters.

Areva has a range of Type B send casks for used fuel, its newest ones beingness TN112 and TN117. Its older TN12/two cask designed for used fuel has been adapted for fresh MOX fuel, and holds 12 PWR fuel assemblies or 32 BWR ones. It is robust, with daze-absorbing covers at each end. Each year Areva moves about 200 casks with used fuel and nearly 20 with vitrified HLW. Fresh MOX fuel and vitrified HLW employ unlike casks than for used fuel. Used MOX fuel requires greater neutron shielding, such as provided by the TN112 cask, which has a double containment barrier and can likewise accept 50 kW estrus load. It has lead shielding with steel, while the older 1 is only forged steel. Both have resin compound shielding. They are both loaded nether h2o.

Holtec's HI-STAR lxxx cask, a multi-layered steel cylinder which holds 12 PWR or 32 BWR high-burnup used fuel assemblies (to a higher place 45 GWd/t) which have had cooling times as brusk as eighteen months. The Hello-STAR 60 cask tin can transport 12 PWR used fuel assemblies. The Hello-STAR 180 was the first one licensed to ship high burn-up fuel, and holds 32 or 37 PWR used fuel assemblies. The Hullo-STAR 190 cask has 38 kW heat load capacity and one version is to be used domestically in Ukraine for PWR fuel*. It is envisaged every bit the main used fuel transport to primal storage or disposal sites in the The states and is promoted as a universal transport cask. It will accommodate all types of spent fuel MPCs used in the USA (namely Areva, Pacific Nuclear, Vectra, NAC, Sierra Nuclear, BNFL Solutions, and Westinghouse). All HI-STAR casks have an aluminium impact limiter at each cease, making the whole unit nearly vii metres long.

* The initial licence by the Usa Nuclear Regulatory Committee covers transport of Holtec's MPC-37 canisters for PWR fuel and MPC-89 canisters for BWR fuel, while Ukraine's SNRIU has certified VVER canisters MPC-31 and MPC-85 for ship in the cask.

In Russia, TUK (transportation packaging fix) casks are used to ship used nuclear fuel. Several TUK-13 casks fit into a container or TK carrier for rail send, each cask holding 12 VVER fuel assemblies (about six tonnes). A larger TUK-1410 cask from the Federal Centre for Nuclear & Radiation Safety has now been licensed to replace the older model for VVER-1000 fuel, both in Russia and from overseas. Each weighs over 100 tonnes, holds 18 VVER fuel assemblies weighing 9 tonnes in a removable canister, and is designed for hotter fuel – up to 36 kW rut load. The TUK-14 series is as well more than heavily shielded, and can carry VVER-1200 fuel. It fits a TK-U-141 railway carrier.

OMZ subsidiary Izhorskiye Zavody has completed the prototype of a new generation of container for the ship and storage of used nuclear fuel from VVER-1000 and VVER-1200 reactors. The TUK-151 container is a thick-walled 2.5m diameter vessel with a sealed lid, a length of about 6 metres and a laden weight of 116 tonnes. Dissimilar the TUK-13 container design, the TUK-151 is not made of stainless steel, only has a low blend steel-plated interior surface that offers "superior strength" and resistance to fracturing at low temperatures nether dynamic loads.

In the UK, 47- or 53-tonne rectangular Type B flasks have long been used to transport Magnox and AGR fuel, which is held in internal skips. In Sweden, more than 80 large transport casks are shipped annually to a central interim waste storage facility called CLAB. Each eighty tonne cask has steel walls 30 cm thick and holds 17 BWR or 7 PWR fuel assemblies. The used fuel is shipped to CLAB after information technology has been stored for most a year at the reactor, during which fourth dimension oestrus and radioactivity diminish considerably. Both these systems are for ship only, not storage.

Spain'south ENSA supplied an ENUN 24P dual-purpose cask to CNNC Everclean in China in 2018, for transporting used fuel from Daya Bay inland to Lanzhou in Gansu province. The ENUN cask is licensed for loftier burn-up fuel, to 57 GWd/tU and, with an external diameter of only 3.3 m, it holds 24 PWR fuel assemblies. The ENUN 32P cask has been used in Spain.

Road transport of used nuclear fuel, Japan. Image: Nuclear Fuel Ship Ltd.

Other ideas for disposal

Numerous options for long-term nuclear waste product management have been considered in the by. The table below highlights a number of these.

| Ideas | Examples | |

| Long-term above ground storage |

| |

| Disposal in outer space (proposed for wastes that are highly concentrated) |

| |

| Rock-melting (proposed for wastes that are heat-generating) |

| |

| Disposal at subduction zones |

| |

| Sea disposal |

| |

| Sub seabed disposal |

| |

| Disposal in ice sheets (proposed for wastes that are heat-generating) |

| |

| Deep well injection (for liquid wastes) |

| |

Long-term above ground storage

Above basis storage is normally considered an acting measure for the direction of radioactive waste (see department above on Acting waste storage). But it has, in the past, been considered as a disposal choice. France investigated it for HLW within the framework of the 1991 law on research into radioactive waste management (Act No 91-1381 of 30 December 1991, besides known equally the 'Bataille Act' after the name of its proposer), but non as a ways of final disposal. However, controlled surface storage over longer time periods (greater than a couple of hundred of years) has too been suggested as a long-term waste management option.

Long-term to a higher place ground storage involves specially constructed facilities at the Earth's surface that would be neither backfilled nor permanently sealed. Hence, this selection would allow monitoring and retrieval at whatsoever time without excessive expenditure.

Suggestions for long-term above ground storage broadly autumn into two categories:

- Conventional stores of the blazon currently used for interim storage, which would require replacement and repackaging of waste material every 200 years or and then.

- Permanent stores that would be expected to remain intact for tens of thousands of years. These structures are often referred to as 'Monolith' stores or 'Mausoleums'.

The latter category of store is derived from the principle of 'guardianship', where time to come generations go on to monitor and supervize the waste.

Both suggestions would crave information to be passed onto future generations, leading to the question of whether the stability of future societies could be ensured to the extent necessary to go along the required monitoring and supervision.

No state is currently planning to implement long-term (i.e. greater than a few hundred years) above basis storage. However, France is investigating long-term acting storage, merely not necessarily higher up ground.

Long-term to a higher place ground storage has been considered as part of the range of management concepts in Switzerland by EKRA (Good Group on Disposal Concepts for Radioactive Waste). EKRA observed that it was unclear what additional steps would exist necessary to show how the long-term above ground storage concept could be brought to the land of evolution comparable with that of geological disposal, and it recommended geological disposal as the preferred option.

Disposal in outer space

The objective of this pick is to remove the radioactive waste from the Earth, for all time, past ejecting it into outer space. The waste would be packaged so that it would be likely to remain intact under most conceivable accident scenarios. A rocket or space shuttle would be used to launch the packaged waste into space. There are several ultimate destinations for the waste matter which have been considered, including directing it into the Dominicus.

The high cost means that such a method of waste material disposal could but be appropriate for separated HLW – i.east. long-lived highly radioactive cloth that is relatively small in volume – rather than spent fuel. The question was investigated in the USA past NASA in the late 1970s and early 1980s. Because of the loftier cost of this selection and the rubber aspects associated with the risk of launch failure, it was abandoned.

Stone melting

The deep stone melting option involves the melting of wastes in the side by side rock. The idea is to produce a stable, solid mass that incorporates the waste product, or encases the waste in a diluted course (i.e. dispersed throughout a large book of rock), and that cannot hands be leached and transported back to the surface. This technique has been mainly suggested for heat-generating wastes such as vitrified HLW (encounter information paper on Treatment and Conditioning of Nuclear Wastes) and host rocks with suitable characteristics to reduce heat loss.

The HLW in liquid or solid grade could be placed in an excavated cavity or a deep borehole. The heat generated by the wastes would then accrue resulting in temperatures groovy enough to cook the surrounding rock and dissolve the radionuclides in a growing sphere of molten material. Every bit the stone cools it would crystallize and contain the radionuclides in the rock matrix, thus dispersing the waste throughout a larger book of rock. There are some variations of this option in which the estrus-generating waste matter would be placed in containers and the stone effectually the container melted. Alternatively, if insufficient heat is generated the waste matter would be immobilized in the stone matrix by conventional or nuclear explosion.

Rock melting has non been implemented anywhere for radioactive waste. There accept been no practical demonstrations of the feasibility of this option, autonomously from laboratory studies of rock melting. In the late 1970s and early on 1980s, the rock melting option at depth was taken forward to the applied science design stage. This design involved a shaft or borehole which led to an excavated cavity at a depth of 2.5 kilometres. It was estimated, simply not demonstrated, that the waste would be immobilized in a volume of stone 1000 times larger than the original volume of waste material.

Some other early proposal was for the heat-generating wastes to be emplaced in weighted, heat-resistant containers such that they would melt the underlying rock, allowing them to move downwardly to greater depths with the molten rock solidifying in a higher place. This proposed option resembles like self-burial methods proposed for disposal of HLW in water ice sheets (see section below on Disposal in ice sheets).

In the 1990s there was renewed interest in this choice, especially for the disposal of express volumes of specialized HLW (particularly plutonium) in Russia and in the United kingdom. A scheme was proposed in which the waste material content of the container, the container composition, and the placement layout would be designed to preserve the container and prevent the wastes becoming incorporated in the molten rock. The host rock would be just partially melted and the container would non move to greater depths.

Russian scientists have proposed that HLW, particularly excess plutonium, could be placed in a deep shaft and immobilized by nuclear explosion. However, the major disturbance to the rock mass and groundwater past the use of nuclear explosions, as well as artillery control considerations, has led to the general rejection of this pick.

Disposal at subduction zones

Subduction zones are areas where one denser department of the Earth's chaff is descending beneath some other lighter, more buoyant section. The movement of one department of the Earth's crust below some other is marked offshore past a trench, and earthquakes commonly occur side by side to the inclined contact between the ii plates. The edge of the overriding plate is crumpled and uplifted to form a mountain chain parallel to the trench. Deep body of water sediments may be scraped off the descending slab and incorporated into the adjacent mountains. As the oceanic plate descends into the hot mantle, parts of information technology may begin to melt. The magma thus formed migrates up, some of it reaching the surface as lava erupting from volcanic vents. The thought for this option would be to dispose of wastes in the trench region such that they would be drawn deep into the Earth.

Although subduction zones are present at a number of locations across the Earth's surface, they are geographically very restricted. Non every waste-producing country would be able to consider disposal to deep-sea trenches, unless international solutions were sought. Notwithstanding, this option has not been implemented anywhere and, as it is a grade of sea disposal, it is therefore not permitted past international agreements.

Sea disposal

Disposal at body of water involves radioactive waste being dropped into the bounding main in packaging designed to either: implode at depth, resulting in direct release and dispersion of radioactive material into the ocean; or sink to the seabed intact. Over fourth dimension the concrete containment of containers would fail, and remaining radionuclides would exist dispersed and diluted in the bounding main. Further dilution would occur every bit the radionuclides migrated from the disposal site, carried past currents. The corporeality of radionuclides remaining in the seawater would be further reduced both by natural radioactive disuse, and by the removal of radionuclides to seabed sediments past the procedure of sorption.

This method is not permitted by a number of international agreements.

The awarding of the sea disposal of LLW and ILW has evolved over time from existence a disposal method that was really implemented by a number of countries, to ane that is now banned by international agreements. Countries that have at i fourth dimension or another undertaken sea disposal using the to a higher place techniques include Belgium, France, Germany, Italia, holland, Sweden, Switzerland, and the United kingdom, as well every bit Japan, Republic of korea, and the The states. This selection has not been implemented for HLW.

Sub-seabed disposal

For the sub-seabed disposal option, nuclear waste containers would be buried in a suitable geological setting below the deep bounding main floor. This option has been suggested for LLW, ILW, and HLW. Variations of this option include:

- A repository located below the seabed. The repository would be accessed from land, a small uninhabited island, or from an offshore structure.

- Burial of radioactive waste in deep ocean sediments.

Sub-seabed disposal has not been implemented anywhere and is not permitted by international agreements.

The disposal of radioactive wastes in a repository constructed below the seabed has been considered past Sweden and the United kingdom of great britain and northern ireland. In comparing to disposal in deep ocean sediments, if it were desirable the repository design concept could be developed so equally to ensure that futurity retrieval of the waste remained possible. The monitoring of wastes in such a repository would also exist less problematic than for other forms of sea disposal.

Burial of radioactive waste matter in deep ocean sediments could be achieved by 2 dissimilar techniques: penetrators or drilling placement. The burial depth of waste matter containers below the seabed can vary between the two methods. In the instance of penetrators, waste containers could exist placed most fifty metres into the sediments. Penetrators weighing a few tonnes would fall through the h2o, gaining enough momentum to embed themselves into the sediments. A key attribute of the disposal of waste material to seabed sediments is that the waste is isolated from the seabed by a thickness of sediments. In 1986, some confidence in this process was obtained from experiments undertaken at a water depth of approximately 250 metres in the Mediterranean Sea. The experiments provided evidence that the entry paths created by penetrators were closed and filled with remoulded sediments of almost the same density as the surrounding undisturbed sediments.

Wastes could also be placed using drilling equipment based on the techniques in utilise in the deep sea for about 30 years. Past this method, stacks of packaged waste material would be placed in holes drilled to a depth of 800 metres below the seabed, with the uppermost container well-nigh 300 metres below the seabed.

In the 1980s, the feasibility of the disposal of HLW in deep ocean sediments was investigated and reported past the Organization for Economic Co-operation and Development (OECD). For this concept, nuclear waste would exist packaged in corrosion-resistant containers or glass, which would be placed beneath at to the lowest degree 4000 metres of water in a stable, deep seabed geology called both for its tedious water menstruation and for its ability to retard the motility of radionuclides. Radionuclides that are transported through the geological media, to emerge at the lesser of the seawater volume, would and so be subjected to the same processes of dilution, dispersion, diffusion, and sorption that affect radioactive waste material disposed of at body of water (run across section in a higher place on Sea Disposal). This method of disposal therefore provides additional containment of radionuclides when compared with the disposal of wastes straight to the seabed.

Disposal in water ice sheets

Since 1980 at that place has been no significant consideration of this option.

Containers of oestrus-generating waste matter would be placed in stable ice sheets such as those found in Greenland and Antarctica. The containers would melt the surrounding water ice and be drawn deep into the ice canvass, where the ice would refreeze above the wastes creating a thick barrier. Although disposal in ice sheets could be technically considered for all types of radioactive wastes, it has only been seriously investigated for HLW, where the heat generated by the wastes could be used to achieve self-burying within the water ice past melting.

The option of disposal in ice sheets has not been implemented anywhere. It has been rejected by countries that have signed the 1959 Antarctic Treaty or have committed to providing a solution to their radioactive waste matter management within their national boundaries.

Deep well injection (liquid)

This approach involves the injection of liquid radioactive waste directly into a layer of rock deep underground that has been chosen because of its suitable characteristics to trap the waste (i.eastward. minimize any further movement following injection).

In order to achieve this in that location are two geological prerequisites. At that place must be a layer of stone (injection layer) with sufficient porosity to suit the waste matter and with sufficient permeability to allow easy injection (i.east. act similar a sponge). In a higher place and below the injection layer there must be impermeable layers that act equally a natural seal. Additional benefits could be provided from geological features that limit horizontal or vertical migration. For example, injection into layers of rock containing natural brine groundwater. This is because the high density of brine (salt water) would reduce the potential for upward movement.

Directly injection could in principle be used on any blazon of radioactive waste provided that it could be transformed into a solution or slurry (very fine particles in water). Slurries containing a cement grout that would prepare as a solid when underground could also be used to aid minimize motility of radioactive waste matter.

Straight injection has been implemented in Russia and the Usa.

In 1957 all-encompassing geological investigations started in Russian federation for suitable injection layers for radioactive waste. Iii sites were found, all in sedimentary rocks. At Krasnoyarsk-26 and Tomsk-vii injection takes place into two porous sandstone beds capped by clays at depths up to 400 metres. Whereas at Dimitrovgrad injection has now stopped, but took place into sandstone and limestone formations at a depth of 1400 metres. In total, some tens of millions of cubic metres of LLW, ILW and HLW have been injected in Russia.

In the USA, direct injection of near 7500 cubic metres of LLW as cement slurries was undertaken during the 1970s at a depth of nigh 300 metres over a menstruation of 10 years at the Oak Ridge National Laboratory, Tennessee. Information technology was abandoned because of uncertainties over the migration of the grout in the surrounding fractured rocks (shales). In addition a scheme involving HLW injection into crystalline bedrock beneath the Savannah River Site in South Carolina was abandoned earlier it was implemented due to public concerns.

Tenorm

Radioactive material is produced or collected every bit a waste from the oil and gas industry and generally referred to as 'technologically enhanced naturally occurring radioactive material' (Tenorm)m. In oil and gas production, radium-226, radium-228 and pb-210 are deposited as scale in pipes and equipment in many parts of the world. Published information evidence radionuclide concentrations in scales up to 300,000 Bq/kg for Atomic number 82-210, 250,000 Bq/kg for Ra-226 and 100,000 Bq/kg for Ra-228. Withal, scrap steel from gas plants may be recycled if it has less than 500,000 Bq/kg (0.5 MBq/kg) radioactivity (the exemption level)n. This level however is 1000 times higher than the clearance level for recycled fabric (both steel and concrete) from the nuclear industry, where anything to a higher place 500 Bq/kg may not exist cleared from regulatory control for recycling and must be disposed of, usually as intermediate-level waste.

The largest Tenorm waste product stream is coal ash, with 280 meg tonnes arising globally each year, and carrying uranium-238 and all its not-gaseous decay products, as well as thorium-232 and its progeny. This is usually simply buried.

The double standard means that the same radionuclide, at the aforementioned concentration, can either exist sent to deep disposal as waste (if chip from the nuclear industry) or released for employ in edifice materials (if contained in fly ash or recycled steel from oil/gas product).

Notes & References

a. In the USA, the Yucca Mountain site in Nevada has been chosen to site a deep geologic repository for disposal of high-level nuclear waste, merely the project is beset past political interference. A licence awarding to construct the repository was submitted to the United states of america Nuclear Regulatory Commission (NRC) by the US Department of Free energy (DOE) on 3 June 2008. However, soon after entering part, the Barack Obama administration decided to cancel the project. After, in June 2010, the NRC's Atomic Safety and Licensing Board (ASLB) denied the DOE'south motion to withdraw the licence application. The order by the ASLB noted the 1982 Nuclear waste Policy Act (NWPA) "does not give the Secretary the discretion to substitute his policy for the 1 established past Congress in the NWPA." The ASLB concluded: "Unless Congress directs otherwise, DOE may not single-handedly derail the legislated decision-making process by withdrawing the Application. DOE'due south motion must therefore be denied." [Dorsum]

b. See the Near Surface Disposal page in the Waste matter Technology Section of the IAEA website (www.iaea.org) for further information. [Back]

c. A brochure on SFR, the concluding repository for radioactive operational waste product, is available from SKB. [Back]

d. Information on the Finnish repositories for operating waste can exist found on Posiva's website. [Dorsum]

e. The Swedish repository programme is described in various SKB publications. Information on the Finnish repositories for operating waste tin can exist plant on Posiva's website. [Back]

f. See Assessment of Disposal Options for DOE-Managed Loftier-Level Radioactive Waste matter and Spent Nuclear Fuel (October 2014), and Disposal options for disused radioactive sources, International Atomic Free energy Agency, Technical reports series, STI/DOC/010/436 (July 2005; ISBN: 9201003056). [Dorsum]

1000. The SAFIR 2 written report - which presented scientific and technical inquiry on the possible final disposal of high-level and/or long-lived radioactive waste in deep dirt layers. [Back]

h. The Swiss National Cooperative for the Disposal of Radioactive Waste product (Nagra) has proposed three siting regions for the loftier-level waste repository. Encounter the Nagra website (world wide web.nagra.ch) for information on management of nuclear waste in Switzerland; in particular Opalinus Clay Project: Demonstration of feasibility of disposal ("Entsorgungsnachweis") for spent fuel, vitrified high-level waste and long-lived intermediate-level waste - Summary Overview, Nagra (December 2002). [Back]

i. The website of the Department of Energy's Office of Civilian Radioactive waste Management (www.ocrwm.doe.gov) stated: "The President has fabricated clear that Yucca Mountain is not an option for waste product storage." (see as well Note a higher up). [Dorsum]

j. The website of the Waste Isolation Airplane pilot Constitute is at www.wipp.energy.gov. [Dorsum]

k. Nirex was incorporated into the Radioactive waste Management Directorate of the Great britain'south Nuclear Decommissioning Potency (NDA) in 2007 and no longer exists every bit a separate entity. The Nirex Phased Disposal Concept is outlined in the Introductory Leaflet What is the Nirex Phased Disposal Concept?, Nirex (2002). [Back]

l. Run across Assessment of Disposal Options for DOE-Managed High-Level Radioactive waste and Spent Nuclear Fuel (October 2014), and Disposal options for disused radioactive sources, International Atomic Energy Agency, Technical reports series, STI/DOC/010/436 (July 2005; ISBN: 9201003056). [Back]

k. In the UK, much of these wastes are exempt from the demand for their disposal to be authorized nether the UK's Radioactive Substances Human activity 1993 because of their low levels of radioactivity. However, some of the wastes are of higher activity and there are currently a limited number of disposal routes available. This includes re-injection back into the borehole (i.e. well-head), which is authorized by the United kingdom's Environment Agency. [Back]

n. The main radionuclide in chip from the oil and gas industry is radium-226, with a half-life of 1600 years as it decays to radon. [Back]

General sources

S. Walker et al, Idaho National Engineering Laboratory, An Overview of In Situ Waste Treatment Technologies, presented at the Spectrum '92 Conference, Boise, Idaho (Baronial 1992)

Malcolm B. Cooper, Naturally Occurring Radioactive Materials (NORM) in Australian Industries - Review of Current Inventories and Futurity Generation, ERS-006, A Report prepared for the Radiation Health and Rubber Advisory Council (Revision of September 2005)

Geological Waste material Disposal page in the Waste Technology Department of the IAEA website

Fact Sheet Agreement the potential for volcanoes at Yucca Mountain, Office of Noncombatant Radioactive waste Management, U.s. Department of Energy, 2002

Deep Borehole Disposal of Nuclear waste: Final Report, Sandia Study SAND2012-7789, Sept 2012

Assessment of Disposal Options for DOE-Managed High-Level Nuclear waste and Spent Nuclear Fuel, October 2014, US DOE

Source: https://world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-waste/storage-and-disposal-of-radioactive-waste.aspx

0 Response to "what does a sit need to hold nuclear waste"

Post a Comment